I. Fundamental Properties

Non-ionic polyacrylamide (NPAM) is a water-soluble polymer characterized by its neutral charge and high molecular weight (typically 6-12 million Daltons) . Its unique molecular structure containing amide groups (-CONH₂) enables exceptional hydration capacity and bridging capabilities without ionic interference .

II. Core Application Domains

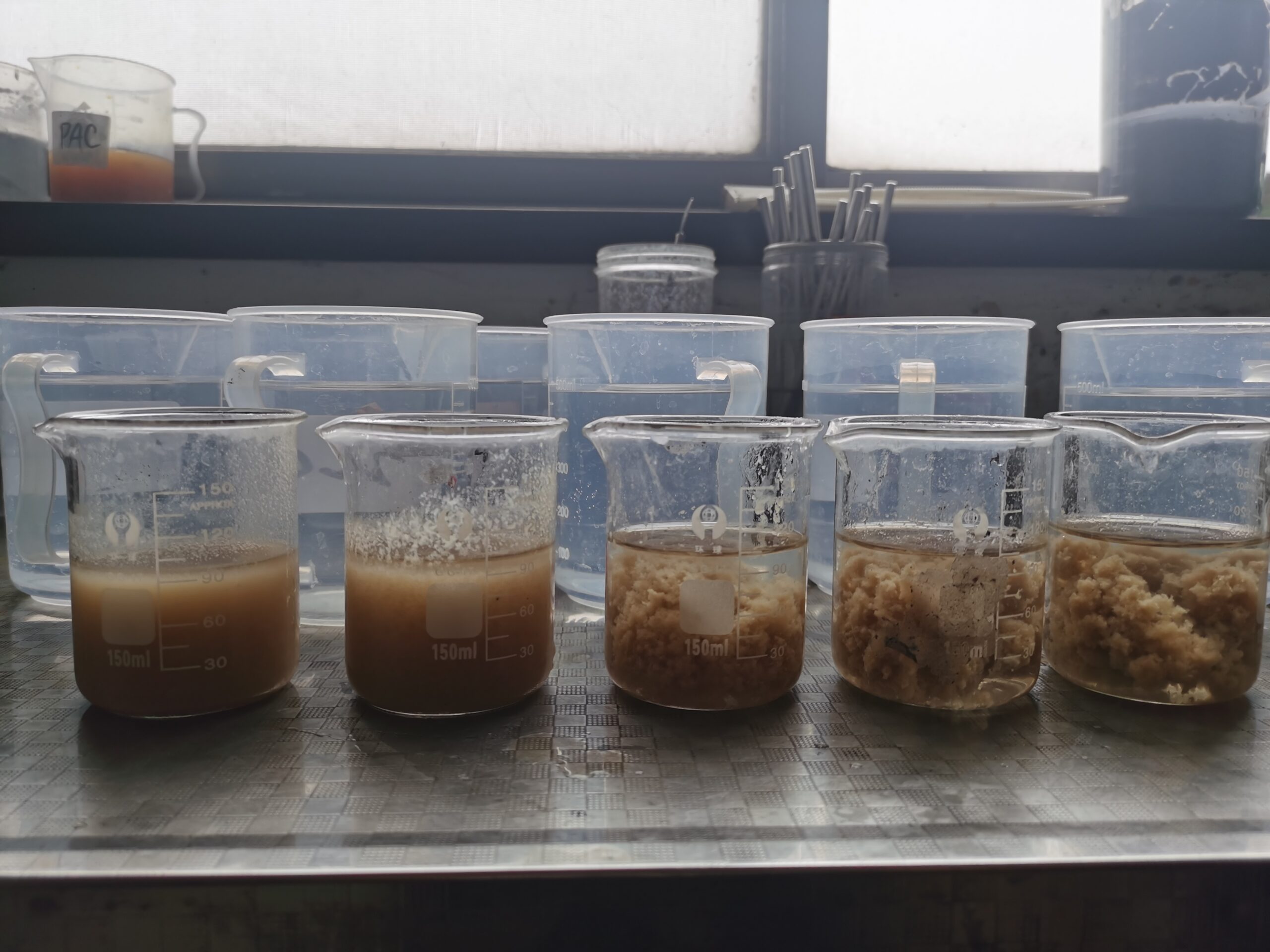

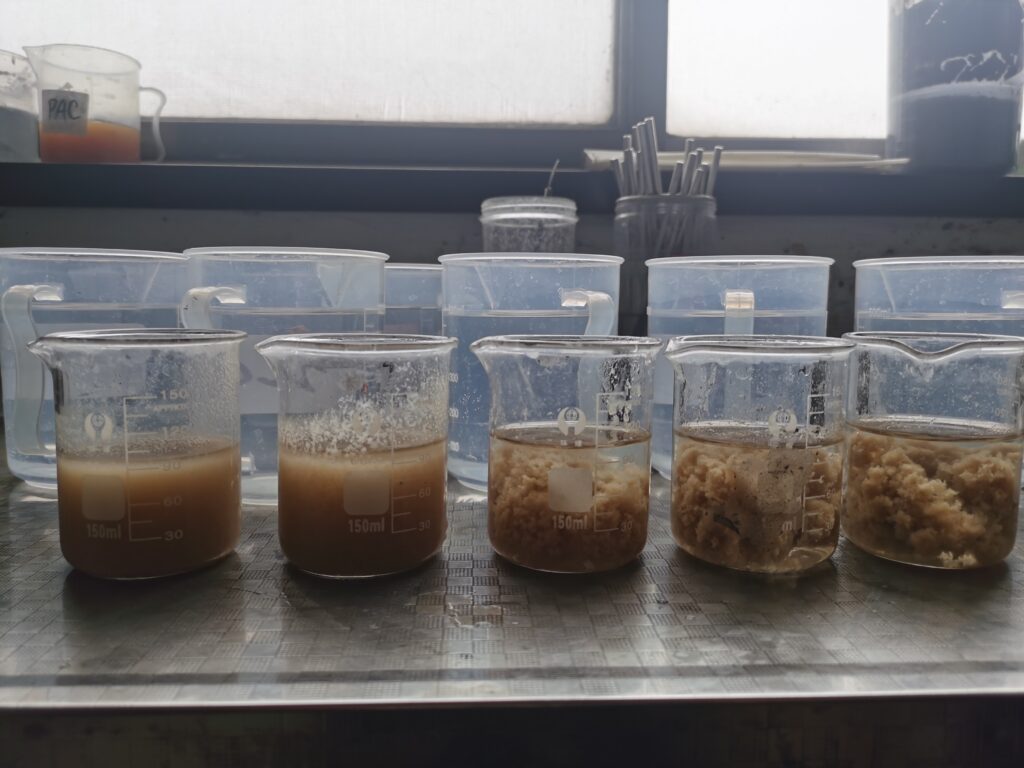

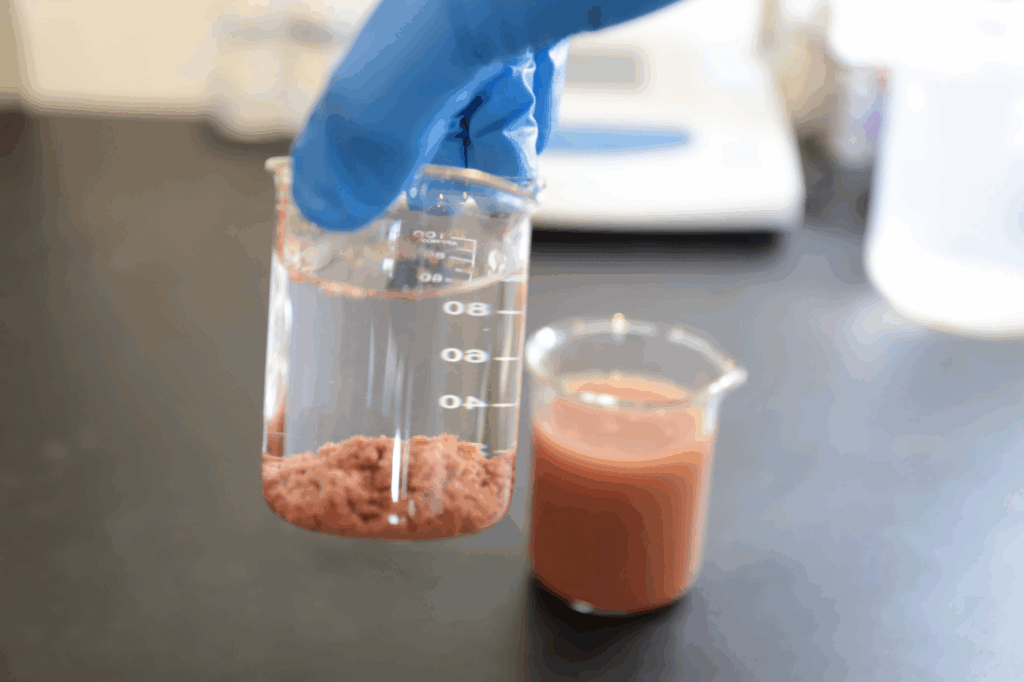

1. Water Treatment

(1) Industrial Wastewater

- Acidic Wastewater: NPAM’s neutrality makes it ideal for pH 3-6 environments where ionic PAMs would precipitate

- Oil Field Production Water: Effective in breaking oil-water emulsions (recovery rates up to 85%) when combined with PAC

- Mining Effluents: Removes suspended solids (300→30 mg/L) from metallurgical and coal wash waters

(2) Municipal Applications

- Sludge Conditioning: Reduces moisture content from 98% to 80% in digestion tanks

- Algae Control: Suppresses algal blooms in reservoirs when applied at 0.5-2 ppm

2. Oil Recovery

- Enhanced Oil Recovery (EOR): Increases viscosity of injection water to sweep residual oil (recovery boost of 10-15%)

- Drilling Fluids: Acts as shale inhibitor in water-based mud systems

3. Paper Manufacturing

- Retention Aid: Improves fiber retention by 20-30% in papermaking

- Dry Strength Agent: Enhances paper tensile strength without affecting drainage

III. Specialized Applications

| Sector | Specific Use | Performance Benefit |

| Textile | Size Agent | Reduces warp breakage by 40% |

| Agriculture | Soil Conditioner | Improves water retention by 25% |

| Construction | Concrete Additive | Enhances compressive strength by 15% |

| Cosmetics | Thickener | Provides shear-thinning properties |

IV. Operational Advantages

- pH Robustness: Effective across wide pH range (2-12) unlike ionic variants

- Salt Tolerance: Maintains performance in high-TDS environments (up to 50,000 ppm)

- Synergistic Effects: When used with inorganic coagulants (e.g., PAC), COD removal increases by 30-50%

V. Emerging Applications

Recent studies demonstrate NPAM’s potential in:

- Microalgae Harvesting: Achieves 90% flocculation efficiency for biofuel production MCP_11]^

- Radioactive Waste Treatment: Combined with diatomite removes 99.9% simulated radionuclides MCP_11]^

- Desalination Pretreatment: Reduces membrane fouling by 40% in reverse osmosis systems